Automotive

The automotive industry remains confronted with multiple challenges, hampering its bottom lines. Some common ones include increasing operational costs, unpredictable demand, supply chain disruptions, and increasing competition. Plural Technology addresses these challenges and helps automotive manufacturers improve efficiency, curtail operational costs, and augment customer satisfaction with a range of technologies like IoT, RPA, AI ML, and AR VR.

How is Plural Technology Driving the Change in the Automobile Industry?

Predictive Analytics

Increasing operational costs is among the most significant challenges of the automobile industry. Some common aspects include increased costs of raw materials, energy, and labor. Predictive analytics can help identify production bottlenecks, enabling the operational organization and downtime reduction. Process automation curbs manual intervention in repetitive processes and increases efficiency.

Machine Learning

Unpredictable demand can lead to costly overproduction or underproduction. With us, enforcing ML algorithms, manufacturers can forecast demand more accurately, depending on historical data and other factors. These algorithms can help manufacturers identify patterns in customer behavior and market trends, enabling them to make more informed production decisions.

Blockchain Development

Supply chain disruptions, no matter the reason, can prove detrimental to automobile manufacturing. However, blockchain solutions can help supply chain disruption risk via a secure and transparent record of all supply chain transactions and interactions. It can help augment transparency, reduce the risk of fraud, and enhance accountability.

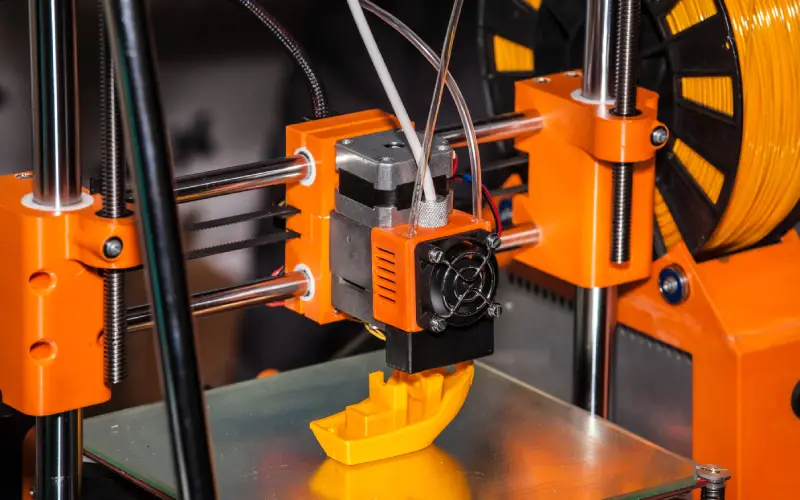

3D Printing

Thriving amidst competition requires providing high-quality products at competitive prices. 3D printing can help manufacturers differentiate themselves by offering on-demand personalized products. It can help curb inventory costs and enable manufacturers to respond more quickly to demand fluctuations.

Product Development and Design

PLM software helps automobile companies streamline product development and design, reduce costs, and enhance product quality. It covers various product development phases and leverage technologies and methodologies to enhance inter-departmental collaboration and efficiency.

Some common features include Engineering Bill of Materials (EBOMs), Manufacturing Bill of Materials (MBOMs), Change management, Requirement management, Variant management, and more. They can be collaboratively used across mechanical, electrical, and software design environments. Plural Technology combines various digital technologies to help manufacturers collaborate more effectively.

Quality Management

Another crucial aspect of PLM systems is helping meet quality standards and regulatory requirements. It includes managing a range of operations like quality inspections and testing, tracking defects and issues, and managing corrective actions. PLM quality management ensures that the product is at par with customer needs, compliant, and efficiently produced. Product designers can harness the capabilities of PLM tools to simulate and test product performance and identify potential quality issues. One of the benefits of PLM quality management is that it can track raw material quality per industry standards.

PLM Supply Chain Management

Manufacturers looking at improving communication and collaboration with other ecosystem players adopt PLM software. It offers them a centralized platform to share information and data, enabling all parties to have access to the same information in real time. Using PLM also enhances the supply chain visibility, allowing manufacturers and suppliers to track product movement across the supply chain.

Choose to be Part of the Digital Future. Partner with Plural!

With an experience nearing two decades, a robust team and unparalleled technology expertise, Plural Technology is a techno-strategic investment to reckon with! We serve multiple industries, including the automobile sector, which is one of our core focus areas. As a technology company, we resonate with the challenges automobile manufacturers face. Accordingly, we’ve ventured into different technologies to help them leverage those most relevant for them to thrive across the demanding digital landscape. Our technology support scope includes AI-ML, blockchain, predictive analytics, PLM, and many more to help automobile players unleash the power of technology and set on a journey to achieving production, strategic, commercial and sustainability goals.